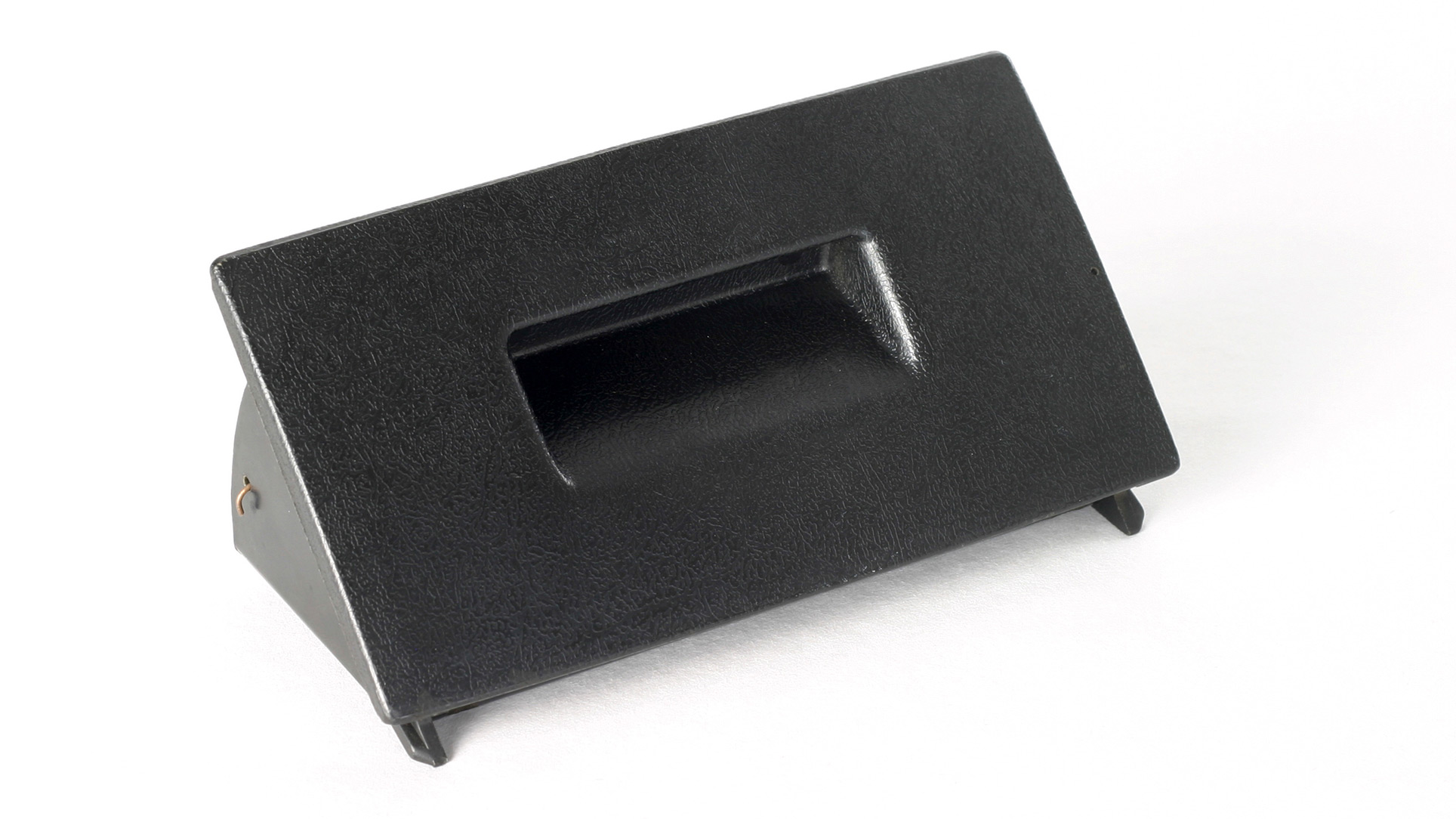

2000: First automotive exterior product: Door entry ledge for Audi

2001: New automotive interior product: Kinematic cupholder with roller blind

2003: Expanding our expertise: Variothermal temperature control technology for high-gloss parts without visible weld line

2004: Inauguration of subsidiary wezi-tec in Legnica/Poland

2005: Expanding our expertise: Plastic-metal hybrid injection moulding

2005: Expanding our expertise: Real and imitation leather lamination

2006: Expanding our expertise: Stack moulding technology for the household appliance industry

2008: Entry into thermoelectrics: First heating/cooling thermo-cupholder in a production vehicle (Audi Q5)

2008: Expanding our expertise: Plastic painting using Powerwash pretreatment and robot technology

2009: Expanding our expertise: Aluminium screens are back-injected with plastic primer-free

2009: Expanding our expertise: 3-component technology for the automotive industry

2014: Inauguration of the Weber Suzhou subsidiary in Suzhou/China

2014: New automotive interior product: Air vents

2016: Car interior innovation: Centre console storage compartment / cupholder unit with double-layer 2-stage sliding lid

Today's sealing putties production

Today's plastic injection moulding production

Dr Thomas Zipp and Andreas Becker

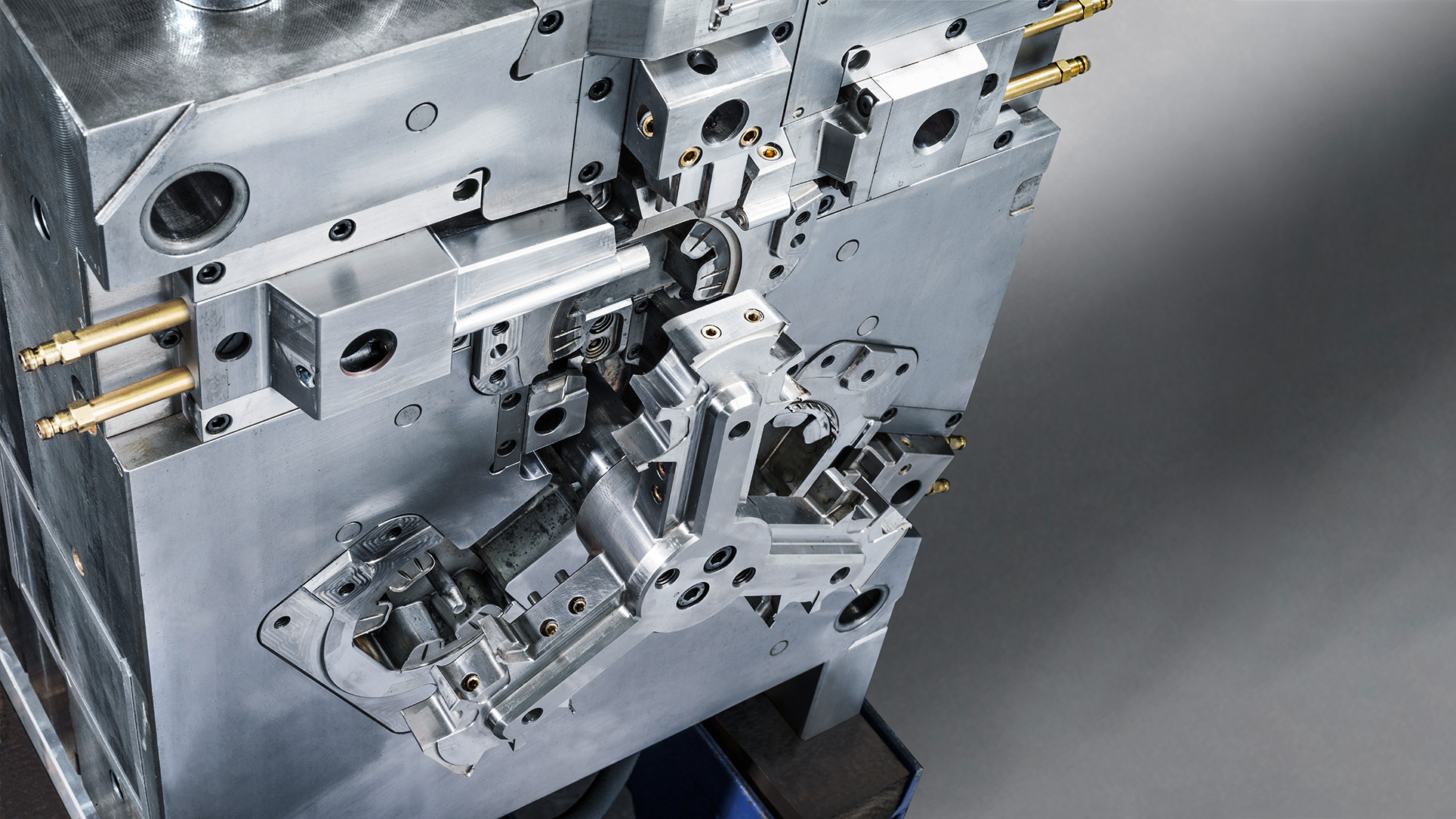

4,000 tonne large injection moulding machine

Opening location Kożuchów

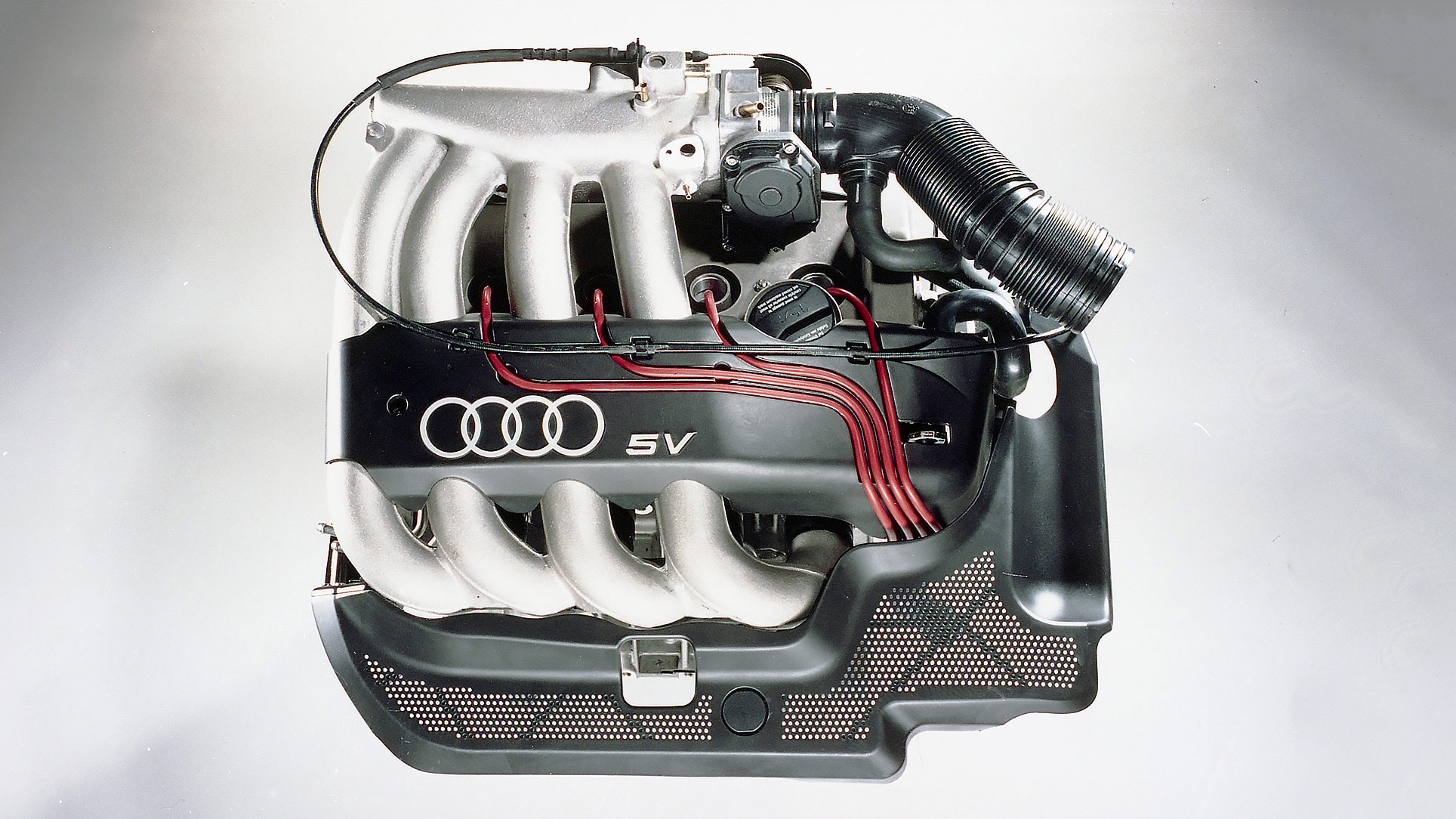

With the 4,000 tonne large injection moulding machine, WEBER invests in technological progress and the future of the founding and parent company site in Dillenburg. WEBER is thus expanding its manufacturing expertise to include large injection-moulded parts such as engine covers, front boots (front luggage compartments) and boot lid covers

1949: Josef Weber founds the company

1949: Entry into the development and production of sealants

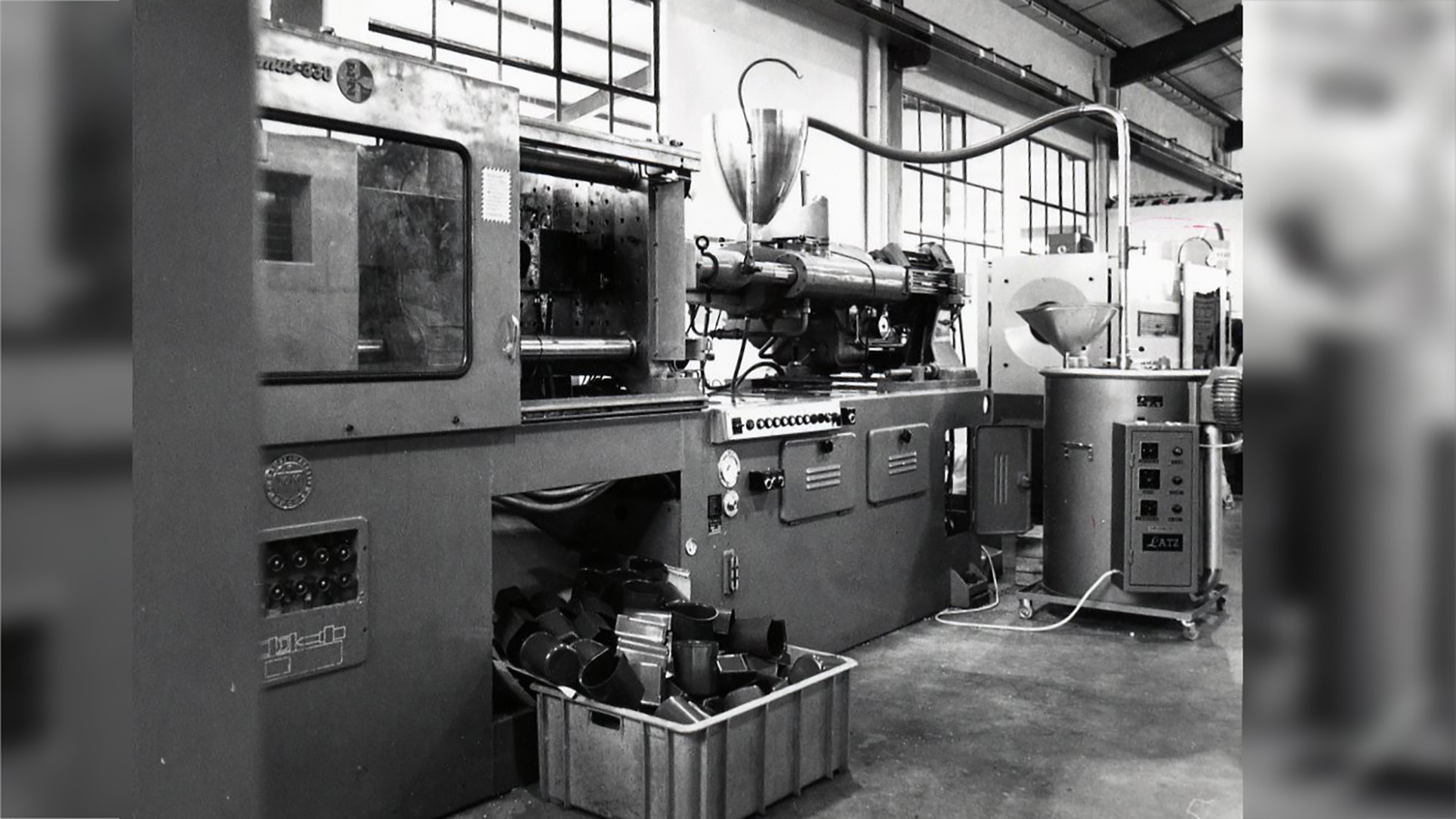

1959: Entry into plastics processing

1959: Start of thermoset pressing for the oven and cooker industries

1959: Entry into mould making

1962: Artur Zipp appointed second general manager alongside Josef Weber

1969: Development of expertise in plastics technology: Thermoplastic injection moulding

1969: Thermoplastic products for the heating industry

1974: Entry into the automotive industry; first automotive interior product: an ashtray for the VW Polo

1977: Entry into the airplane industry; first interior product: Ceiling panels for the Airbus A300

1994: First automotive powertrain product: Engine cover for the VW Group

1995: Dr. Thomas Zipp appointed general manager alongside Artur Zipp

1998: Product launch W-1000: Development of the first segregation-free mineral cartridge cement